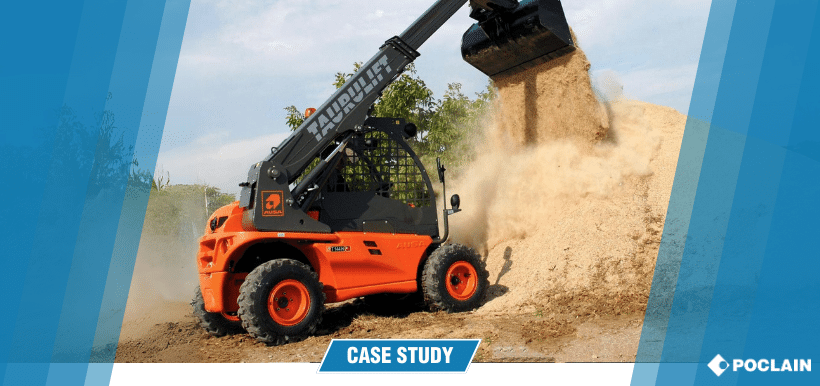

[Case Studies] Tilt, Lift, Extend – A Poclain Valve Block Controls AUSA’s Telehandler Boom

Telescopic handlers, known for their versatility and durability, have gained popularity in both construction sites and farms. These machines serve multiple purposes, functioning as forklift trucks, loading shovels, aerial work platforms, and cranes. Achieving optimal performance in these multifaceted roles requires the use of precise and dependable components. Ausa, a compact telehandler manufacturer, has selected custom diverter valve blocks from Poclain to control the boom of their 144H and 235H models.

Custom valve blocks by Poclain for boom control

With their forward and upward lifting capabilities, telehandler booms are more complex than those of forklift trucks. As a result, they integrate three valve functions: one for extending the boom, one for lifting the bucket, and one for tilting it. Prior to their collaboration with Poclain, Ausa used three separate standalone valves, each installed at different locations on the frame.

In 2017, Poclain delivered the first prototype custom valve block that combines all the boom functions, as well as the safety function to prevent the machine from tipping forward. The port locations and mounts of the blocks are tailored to seamlessly integrate with the telehandler's architecture.

Simplified frame design and assembly

Ramon Cano, the Mechanical and Hydraulics Technology Manager at Ausa, affirms the advantages of using Poclain's valve blocks. "They simplify our system design and assembly, resulting in cost savings. Installing these blocks requires less piping and mounting compared to standalone valves." Additionally, managing inventory is more streamlined, as there is only one part number instead of three. Poclain collaborated closely with Ausa to optimize the dimensions of the valve blocks, ensuring they can withstand the oil pressure while fitting snugly beneath the trunk for easy access. Two blocks, which share the same configuration, are sized for flow rates of 20 and 70 liters per minute for the 144H and 235H models, respectively.

Ramon further notes, "Poclain's valve blocks have been in operation for nearly four years, and we have encountered no issues." Ausa is actively working on a zero-emission model, the T164, which can be powered by either an internal combustion engine or an electric motor, and they plan to incorporate Poclain's valve block into this innovative design as well.

Interview with Ramon CARO,

Mechanical and Hydraulics Technology Manager at Ausa

>> Learn more about Poclain's diverter valves

With a capacity ranging up to 400 l per min., Poclain's selector – diverter valves come in several formats: standalone, modular, flanged or integrated in multifunction blocks. Their exceptional volumetric efficiency provides low pressure drop to the transmission.

Do you want to know more?

Visit us on Agritechnica, Hannover, Germany, November 12-18, booth #B16, hall 16