TBM – Tunnel Boring Machine

Poclain Hydraulics has more than 30 years’ experience on TBM Market. With more than several hundred motors supplied each year for Tunnel Boring Machines across the world, Poclain Hydraulics is a leader in this industry. Our hydraulic motors have been widely used and re-used at the main TBM Manufacturers in Asia, Europe and USA.

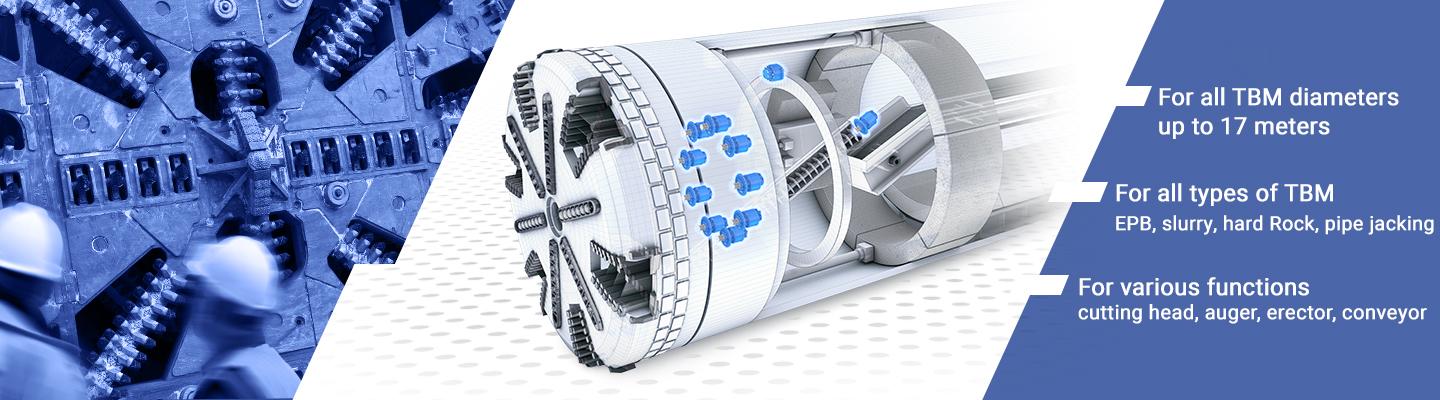

Solutions for all TBMs, any diameter

Poclain Hydraulics solutions address all types of TBMs from <1m up to 17m diameter and different functions.

Various Environments:

- Road

- Railway

- Subway

- Hydropower

- Pipelines (TV cables, Gas distribution...)

Different TBM Types and Diameters:

- From 0,5m to 17m, including mini and micro

- Slurry / Mixshield

- Earth Pressure Balance

- Single and Double Shield

- Hard rock

- Multi-mode

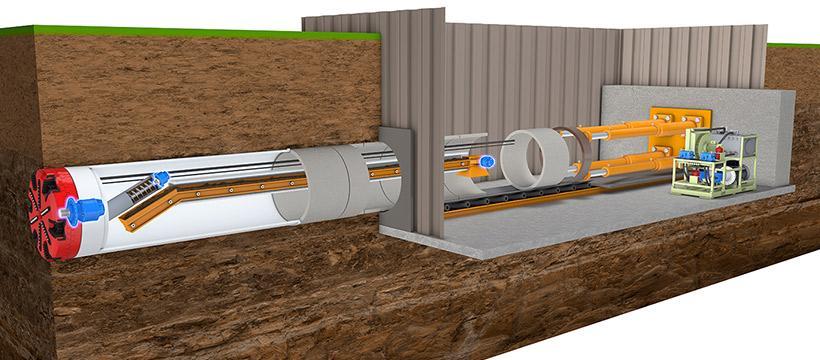

- Pipe jacking

From cutting head to agitators, we cover main TBM’s functions

Our offer addresses main functions of the TBM: Cutting Head, Auger Drive, Erectors, Agitators and various additional functions of the backup system.

CUTTING HEAD:

Cutter head motors in TBM operate the cutting shield. Their design criteria implications for the efficiency and performance are critical to maintaining project schedules. Choosing the right cutter drive has strong impact on machine assembly, safety and reliability.

Two different motor ranges meet the demands of various TBM cutter head sizes :

• MS50 (6 l per rev) to MS 125 (15 l per rev), shaft output as well as smaller sizes for pipe jacking options

• MI250 / 330 (20-40 l per rev) with hollow shaft

MS and MI motors in a closed loop system reduce system components (gearboxes, water cooling systems), dimensions and potential failure points, for clear advantages in terms of integration (weight and length), synchronization and safety.

Features:

• Multiple speeds

• Reinforced bearing and sealing

• Permanent rotation synchronization and outstanding torque with direct drive

ERECTOR:

Reinforcing the tunnel walls demands a high level of precision and security. Poclain hydraulics MS motors’ modularity enable them to meet the needs of TBMs from EPB to shield-slurry and multi-mode types.

MS motors from MS02 to MS83 offer the features necessary to meet support erector functions:

• Parking brake

• flanged counterbalance valve for optimal segment positioning

• high starting torque

• low inertia equating to high precision

AUGER:

For maintaining the constant balance pressure of EPB type machines as well as providing effective removal of the excavated material, the motor needs to meet high productivity and reliability constraints. Poclain Hydraulics’ MS motors from MSE02 – MS125 make that possible for screw conveyors in TBMs up to 17m as well as for augers in pipe jacking TBMs.

Features:

• Direct drive, end of the screw installation

• Compact envelope optimizing screw conveyor integration and set-up

AUXILIARY FUNCTIONS:

Mixer

Ensuring the waste soil extracted with the proper consistency means addressing shock loads and pressure peaks. MS motors in MS08 to MS50 sizes help TBMs achieve optimal soil paste consistency for effective evacuation of excavated materials.

Features:

• high output torque

• reinforced bearing and sealing

• steady motion at low speeds

Conveyor

Removal of overburden or spoil demands efficient and continuous work from the belt drives. MS motors from sizes MS08 to MS18 deliver low maintenance, compact and robust solutions to support this function for TBMs.

Features:

• direct drive

Shotcrete arms

Like the erectors, the shotcrete arms need a high level of precision to ensure the concrete pistol maintains the right position. MS motors from MS05 to MS11 support this function in hard rock TBMs.

Features:

• parking brake

• flanged counterbalance valve for precise positioning

A unique design

Thanks to their unique design our motors offer high performance, compactness, robustness; one of the best power density on the market, easing integration in limited space with the ability to withstand strong variation of pressure and power, it makes our products especially suitable for this application progressing in inhomogeneous ground geology.

A worldwide integration and technical support network alongside Poclain Hydraulics’ low maintenance components deliver reliable performance to boost uptime for TBM applications.

What do you gain?

Performances

- High starting efficiency

- High torque even at low speed

- Full hydraulic Synchronisation while using multiple drive

- Multi Speed & Free-wheeling for flow optimization

Integration

- Modular design, more flexibility

- Direct drive, no gearbox

- Very High Power Density

- Compact: minimum Length and Diameter

- Cutting head design possible for short radius TBM

- Integrated parking brake and flanged valves

- Low weight

- Closed loop self cooling system

Safety

- Stability in all ground

- Direct drive: high torque peak or high acceleration with no failure

- High speed and power variation supported

- Safety valves to protect the system and to face ground environment variation

- High braking torque capacity

- Reinforced design (sealing & bearings)

Do you want to know more about this application ?