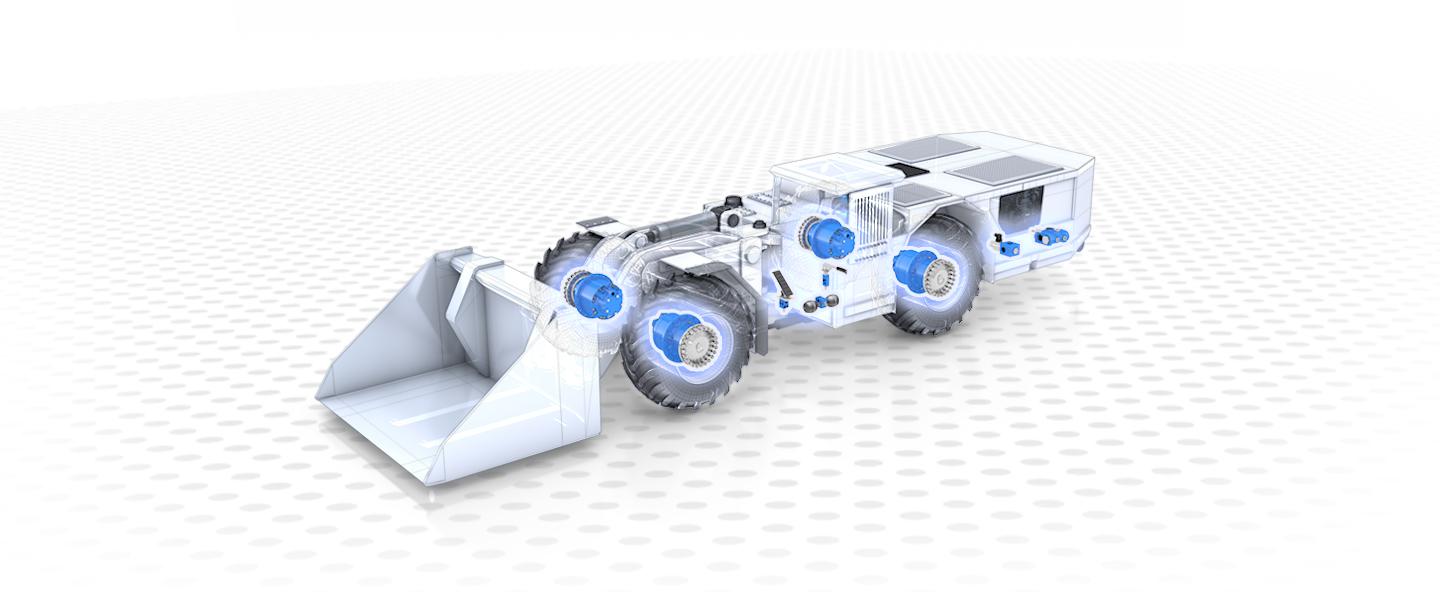

LHD - Underground Mining Load Haul Dump Loader

Increased operational complexity, stringent mining regulations and productivity demands challenge the underground mining industry. Underground LHDs’ material transporting roles play an integral in enabling mining operations to overcome these challenges. As a mining OEM, you need to ensure your machines deliver on performance reliability, operator comfort, and safety. Poclain Hydraulics’ powerful solutions help you ensure your machine’s prime mover and braking system meets your customers’ production economy goals safely and reliably.

LHD Full Power Transmission Solutions

Underground mining equipment needs to deliver on optimized productivity in demanding, highly explosive environments. In hard-rock mining applications, large-scale developments, and narrow vein mining, tough, and efficient powertrain technology can make this possible. Poclain Hydraulics offers proven, reliable and robust systems.

- Small class: up to 3T payload (1 m³ - 1.5 m³ bucket capacity) – successfully transmission equipped with MSE18 motors

- Medium/ Heavy class: up to 8T payload (2.8 m³ - 3.5 m³ capacity) – successfully transmission equipped with MS83 motors

- Extra Heavy class: up to 10T payload (3.5 m³ - 4 m³ bucket capacity) – successfully transmission equipped with MS125 motors

Give your operators optimal productivity, safety, and precision

Our compact and modular MS line of low speed high torque motors help you adapt your machine width and length to meet your customers narrow turning radii and adjust to various space constraints across different machine frame styles. Our direct drive wheel motor design allows for high power density in a compact envelope helping you integrate the power you need into limited height designs. Our robust bearing design helps you deliver the load capacity your customers need in order to maximize hauling capacity and minimize extraction costs.

Precise operator control and safety reduces operator fatigue directly contributing to better productivity. Our motors allow you to deliver a machine designed for precise maneuverability. Thanks to low internal inertia, our motors are capable of quick direction changes helping your machine operators decrease cycle times.

The versatile design of our MS motors integrates many functions such as multi-speed, speed sensors, as well as static and dynamic multi-disc brakes. This integrated design helps you reduce required maintenance and potential failure points, increasing up-time for mining operators in an industry where TCO must be minimized.

Direct drive wheel motor technology makes advanced design flexibility possible such as articulated steering and 4WD options for the controllability your customers require.

Meet Safety and Anti-Explosion Environment Regulations with our Braking Solutions

In underground mining, machines must be equipped for long descents calling for a high-performance wet brake solution. The new generation of oil-immersed brakes available on our MHP motors meet anti-explosion regulations. Coupled with the VB3 valve range, our MS motors meet a number of your requirements: low-pressure drop, space constraints, short response time, safety, reliability and top performance.

On top of our multi-disc braking offering, full control systems including valves and electronics are available to round out our power transmission offering and give your customers the added capabilities they demand while simplifying your supply chain and logistics.

Unpredictable surface conditions mean operators need to be prepared for various ground adherence situations. The SD-CT constantly monitors and adapts the drive wheel speed to the ground conditions by reducing oil flow to wheels experiencing slippage ensuring constant productivity.

Be confident in our ability to support your machine, no matter where you are

Regardless your location, our experts are there for you throughout the development of your LHD. They provide data, settings help, and prototype delivery on top of an easy-to-integrate solution.

Quality performance is in line with the highest LHD requirements. With our standard line of production, we deliver the same process and the same level of quality. Our reliable and trusted propel solutions for LHDs equip leading OEM machines.

Training and continuous improvement – Poclain Hydraulics training and support doesn’t stop once your machine goes into series. Our standard or personalized trainings help you ensure your team knows our products and is ready to deliver competent support to your customers.

> Learn more about our training offers