XXL MI250s POWER KUBOTA’S PRE-SHREDDERS

Kubota Environmental Services Co. Ltd pre-shredder

Horizontal and vertical shredders are Kubota Environment’s primary business. The vertical models shred small, mainly metal components at high speed. Their horizontal single and twin shaft models are used for more pliable non-metal material. On the top of their range are the extra-large pre-shredders and shredders that process cars, fridges, and large metal structures at low speed. A total of 30 units are manufactured every year, combining electric and hydraulic drives. Kubota Environmental’s success stems from their attachment to outstanding after-sales service, which has triggered repeat business from several customers.

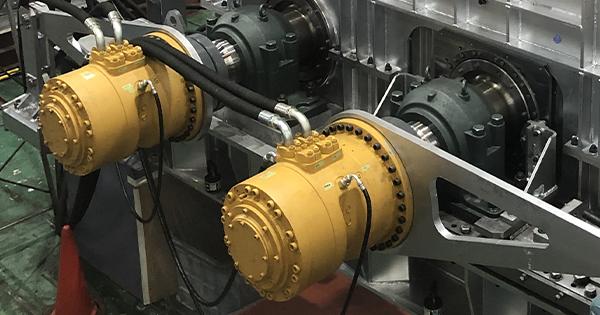

Kubota started working with Poclain Hydraulics in 2019 on a 2 x twin-shaft hydraulic pre-shredder dedicated to nuclear accident waste. Poclain Hydraulics’ solution consisted of six 30-liter MI250 motors. It outperformed the competition in terms of quality, pricing, and lead-times. The compact size of the MI250 enabled Kubota to mount two motors on the same side of the machine and simplify assembly, as the hoses were bundled together. In terms of behavior, the MI250 accelerates smoothly and can withstand the pressure peaks generated by the material’s varying degrees of hardness. Responsive aftersales services are also critical in the waste shredding industry, as the machines often work 24/7, and repairs must be swift. For the first delivery, Kubota needed Poclain Hydraulics to overhaul two MI250 in a short timeframe. The motors were sent to the Yokohama certified repair center and serviced within the required deadline.

Kubota is delighted with the performance and the services of Poclain Hydraulics and is currently producing its third shredder powered by MI250 and MS125 motors.

The collaboration between Kubota and Poclain Hydraulics is likely to grow. They expect their supplier to help them access new markets, with more powerful shredders powered by larger motors than the existing MI250.

Learn more about Poclain Hydraulics solutions for industrial shredders.