[DISTRIBUTOR INTERVIEW] GETTING TO KNOW A.T. HYDRAULICS

Up first, Poclain Hydraulics interviews Robert Mack of A.T. Hydraulics. Robert Mack has been with what became A.T. Hydraulics Queensland for 24 years, and has worked with Poclain Hydraulics products since 2008.

The distributor relationship with A.T. Hydraulics is one of Poclain Hydraulics’ oldest partnerships, originally beginning in the late 70s and the Poclain Hydraulics H series wheel motors at a time when A.T. Hydraulics was still called “Energy Hydraulics”. In the early 1990’s, Energy Hydraulics split up, and A.T. Hydraulics was formed. Couple that with an acquisition in 2008, and A.T. Hydraulics now has locations in Queensland, Sydney, and Perth in Western Australia, allowing them to serve the whole of Australia’s fluid power market.

What sets A.T Hydraulics apart? One word – experience.

Robert Mack: “A.T. hydraulics has a lot of experience, hundreds of years. In Queensland alone we have 200 years combined experience in this industry, which I feel is quite rare in this day and age.”

Where does A.T Hydraulics specialize?

RM: "A.T. Hydraulics offers in-house repairs and hydraulic equipment testing as well as design, manufacture, installation and commissioning of hydraulic systems, power units, or machinery. A.T. Hydraulics caters mainly to the Australian market specializing in a number of markets from mining, waste collection vehicles, and dust extraction machines to theme park repairs, film studio special effects.

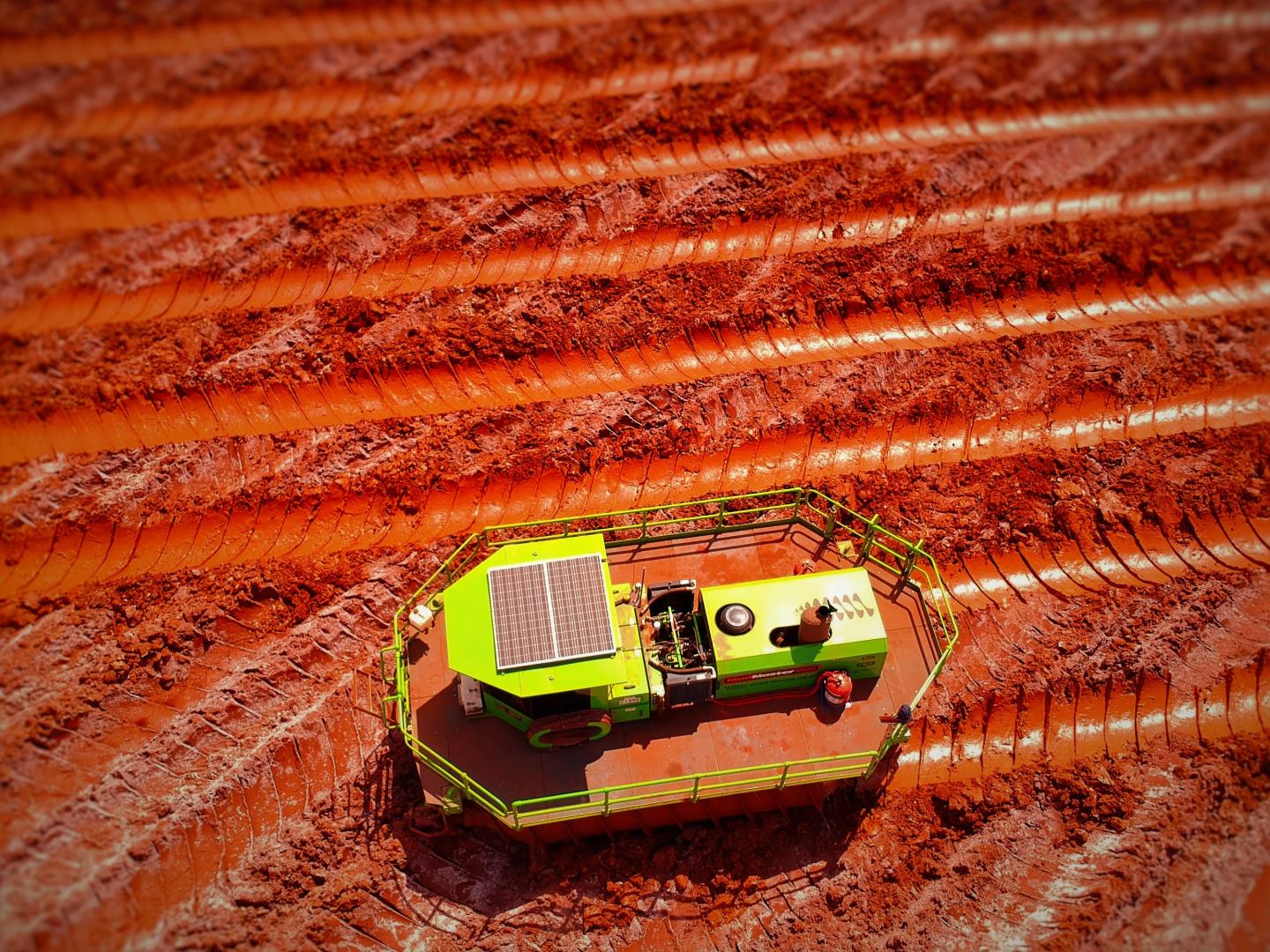

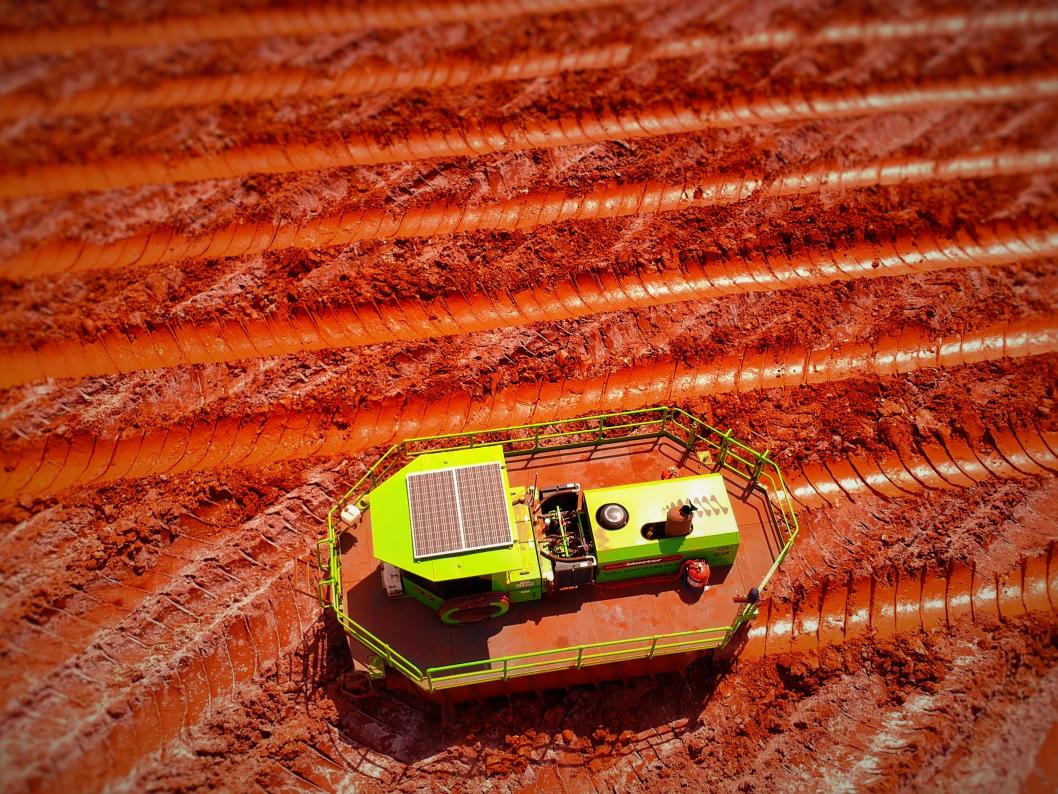

Mining is an area of specialty for A.T. Hydraulics. Recently, A.T. Hydraulics and Poclain Hydraulics collaborated on an OEM project for Phibion for their tailings pond machine, the MudMaster®. The MudMaster integrates a Poclain MS83 to drive the worm wheel of the worm drive. The radial piston, cam lobe technology coupled with a special sealing on the bearing support to protect from contaminants that are common in this type of application, gives the machine the power and traction needed to manage tailings dams safely and efficiently. They also need a special encoder to allow for digitalization and precise electronic direction control, and A T H does the motor modification in order to offer this option to the customer."

RM: “We have also completed a number of applications for the rail networks and in these applications we’ve used the CreepDrive unit as well as the MS05 wheel motors for Queensland Rail.”

Beyond mining and rail network support, A.T. Hydraulics does a lot of work with dust extraction machines, working with a number of large OEMs some integrating the Poclain Hydraulics axial piston pumps.

Another interesting niche for A.T. Hydraulics is their work on special effects and theme parks. Robert Mack recalls a special effects project for the “Aquaman” movie where a Poclain wheel motor simulates the movement of a wave hitting a car.

RM: “In Queensland we specialize in theme park applications and repairs and have worked closely with Warner Brothers Studios to create special effects applications on major motion feature films. One project I enjoyed being involved with was a special effects scene where we applied a Poclain Motor to rotate a suspended vehicle.”

Customer Approach

A.T. Hydraulics works closely with Poclain who takes a consultative role when dealing with their clients. They work hand in hand with both Poclain management and application engineers to propose well-adapted solutions to customer OEMs or end-users in the region and maintain that expert role supporting their customers right up to a smooth commissioning of new machines.

RM: “Before commissioning an application we ensure that our start up procedure has been completed correctly and thoroughly so we do not encounter any problems for our customers. After an application is commissioned we provide our customers with technical and hands on after sales support. Our process has been highly successful over the years.”

Authorized CRC – What does that mean?

RM: “We have worked closely with Poclain Hydraulics for a very long time and we are known within the industry as being Poclain distributors. We are the only recognized authorized repair centers in Australia in two locations Brisbane, Queensland and Sydney, New South Wales. Through Proclain’s CRC auditing criteria Proclain ensures our product repairs are of the highest standard. ”

Learn more about A.T. Hydraulics at their website.

Contact our Australian distributors.