GET TO KNOW POCLAIN MEDIUM DUTY CLOSED LOOP PUMPS

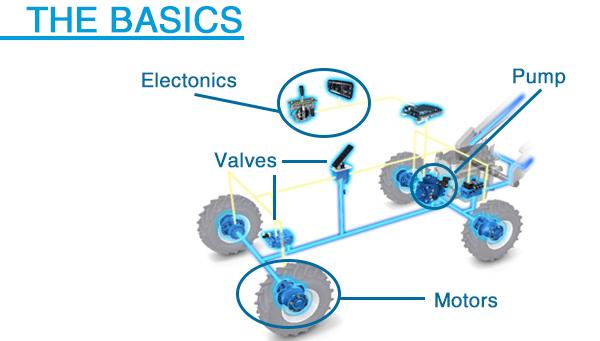

The basics:

A closed loop axial piston pump enables mobility with a hydrostatic transmission generally comprised of

- An endothermic engine

- A closed loop variable displacement pump

- A hydraulic wheel motor

This type of configuration makes the most sense for mobile machines if you need to achieve:

- Variations in speed

- Brake function

- Traction

The pump’s reversibility is what makes this possible in a closed loop circuit. An open loop circuit would require both a hydraulic distributor to reverse the direction of the flow and an additional hydraulic component to address braking.

With two hydraulic pump loop options, open circuit or closed circuit, a closed circuit loop saves valuable system space by offering continuous fluid flow without the need for additional parts. In comparison, an open circuit loop typically requires a larger reservoir and as a result, increases the system’s footprint.

What about local support?

Poclain believes in delivering global expertise at a local level. Poclain pump experts, design offices and lab facilities are located across the globe with various locations or support in Europe, North America and Asia Pacific. Additionally our application engineering teams can suggest the best solution for each application and market in Europe, North America, and Asia Pacific.

Want to learn more?

https://www.poclain-hydraulics.com/en/products/pumps

Up Next… Spotlight on our PM closed loop Axial Pump product range

Author: Filippo Ganzerli, Axial Product Marketing Manager