TEMPERATURE AND THE EXCHANGE VALVE

Heat build-up is a natural by-product of a closed-loop circuit.

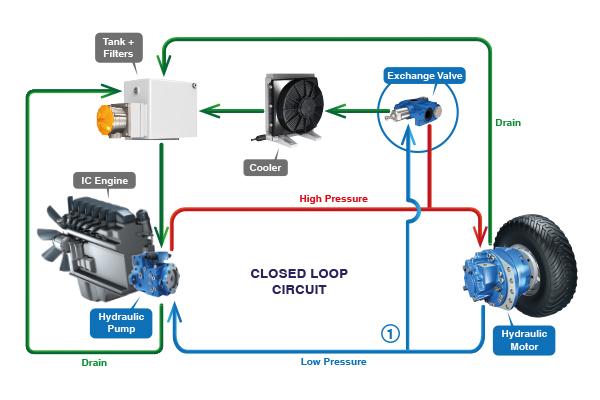

Closed-loop circuits are ideal for mobile transmissions. They allow for smaller components, a pre-requisite to fit inside a vehicle. A small amount of oil – 10 liters at the most - circulates within the circuit. So heat build-up is a natural by-product of a closed-loop circuit, and it averages 25 to 30% of the engine horsepower. On a Poclain Hydraulics closed-loop circuit, the recommended oil temperature is 50 to 80°C (120 to 175°F).

Several factors impact oil temperature

The closed-loop configuration implies that every part in and around the system impacts the oil temperature.

1. The size of the hoses

Undersized hoses make oil travel faster and generate heat.

2. The size of the components

The size of the transmission components impacts the oil temperature. Undersized motors and pumps are subject to a higher pressure and generate more heat.

3. The auxiliary circuit(s)

If the vehicle integrates auxiliary functions that feed off the same tank, they will also impact the oil temperature.

4. The climate

The climate impacts the oil temperature. Poclain Hydraulics transmissions are designed to operate in any climate: the components on a tree harvester are the same, whether they operate in a forest in Sweden or Brazil. However, the oil type will change. In a mild climate, HV46 is recommended, HV32 for cold temperatures and HV68 or HV100 for hot temperatures.

How the exchange (hot oil shuttle) valve works

The impact of the exchange valve was measured on a Poclain Hydraulics prototype vineyard tractor. The oil temperature reached 140°C (285°F) without the exchange, and peaked at 80°C (175°F) with the exchange.

The exchange valve’s role is to bleed hot oil from the low pressure side (1) for cooling, filtering or to provide oil for pump or motor case flushing.

The Poclain Hydraulics guidelines set the ratio of diverted oil at 10 to 15% of the main pump displacement.

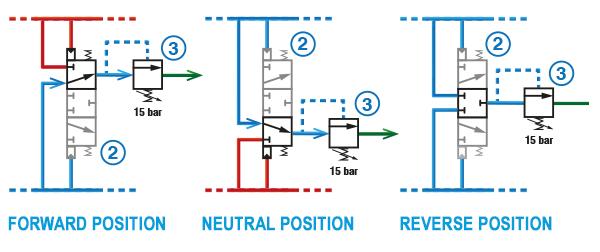

An exchange valve consists of a low-pressure selector (2) that automatically connects the valve to the low-pressure line. The oil goes through the selector and into the exchange relief valve (3). It then exits the valve and goes to the cooler and the tank.

Once the extracted oil reaches the tank, it is sent to the charge pump that reinjects the oil into the closed loop.

The exchange valve functions both in forward and reverse: in reverse, the high and low-pressure lines switch over. The selector valve shifts up, this time letting in the oil from the upper line. When the circuit is idle, no oil enters the exchange valve.

To secure the flow transiting through the exchange valve at 10 to 15%, the pressure settings of the exchange and the charge relief valves are adjusted. The wider the gap between the two pressure settings, the higher the flow transiting through the exchange valve. If both valves are set at 20 bar, no oil goes through the exchange valve.

The best place for the exchange valve

The goal is to limit the pressure drop between the exchange valve and the charge relief valve housed in the pump. So the ideal location is close to or inside the pump. On compact machines such as skid steers, the pump and motor are close, and the exchange valve can also be housed inside the motor.

As the closed-loop diagram shows, there are three hoses connecting to the exchange valve. Integrating it to the pump or motor, depending on the circuit layout, is preferred to having it standalone to simplify hosing and coupling.

Not all applications need an exchange valve

A few applications, such as walk-behind compactors, work at low speed and generate little heat. To determine the need for an exchange valve, a Poclain Hydraulics field technician carries out a circuit temperature assessment during the application commissioning.

The exchange function is available in several sizes

The higher the main pump displacement, the higher the volume of oil that must transit through the exchange valve. Poclain Hydraulics offers three sizes: the VE10, 30 and 60, respectively enabling a flow of 10, 30 and 60 liters per minute.

Article contributors:

Michael CALMELS, Technical Trainer; Cyrille D HERSIGNERIE, Technical Trainer; Stéphane JUDLIN, Technical Trainer; and Yvan LE BOUGEANT, Test Center Manager

To learn more about our exchange valves or hydrostatic transmissions in general, contact Poclain Hydraulics Training Center