GRAND PARIS: BEHIND THE SCENES SITE VISIT WITH POCLAIN CUSTOMER, TMS

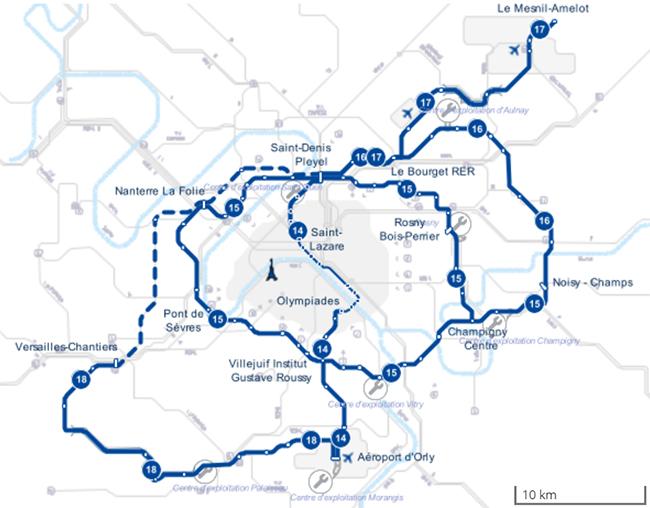

The Grand Paris Express covers a 5,000 km2 zone and impacts 70 municipalities around Paris not to mention the major real estate programs spurring from the creation of the new stations. The area covered by Line 15 South will connect 16 stations from Pont de Sèvre to Noisy-Champs in 37 minutes. It concerns one million inhabitants, 22 municipalities and 4 departments. On the site of this civil engineering project, which began 18 months ago, Poclain joined TMS (Techni-Metal-Systèmes), a French subsidiary of the HERRENKNECHT group, world leader in the construction of tunnel boring machines.

“It was an enriching and extraordinary site visit!” Laurent Camin, Poclain Hydraulics Sales Engineer at Poclain Hydraulics.

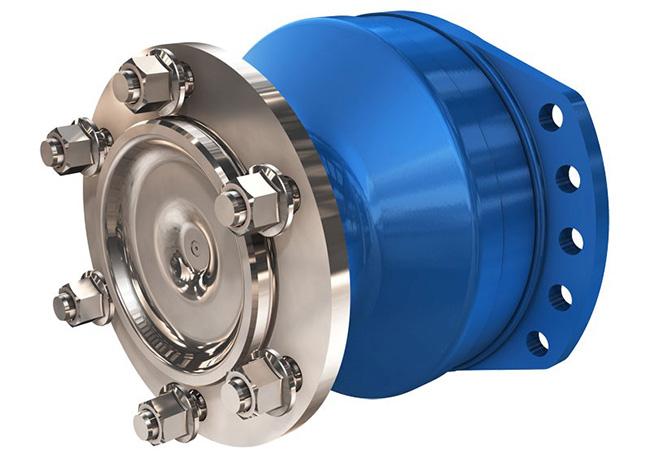

MSVs designed to carry more than 130 tonnes

From the rooftop of a neighboring building, the group had an impressive view of the 50-meter deep Arceuil-Cachan shaft and a great vantage point to see a lot going on down below the surface. The two underground TMS MSVs equipped with double cabins are working inside the 7.6-meter diameter tunnel along a 3,500 meter section of metro. From either end, each vehicle’s charge consists of seven tunnel segments or 56 tonnes plus a mortar tank for a total payload of 98 tonnes and gross vehicle weight of 130 tonnes. Out of 16 MSV wheels, eight are driven by MS18 Poclain Hydraulics motors with integrated parking and dynamic brake. The system also included VB brake valves in each of the cabins as well as a VB200 valve for emergency braking. Once loaded, the MSVs make the trip to the TBM to unload the material via an entry in the back of the TBM.

On board the PSV to for a look at the TBM

Using the construction elevator to reach the tunnel entrance, the team followed the MSV using the PSV (Personnel Service Vehicle) to get to the 200-meter-long tunnel boring machine, working 3km away from the shaft. The PSV is equipped with Poclain Hydraulics MS05 motors and VB brake valves. "It's a great experience to see this immense machine [the TBM] in operation that digs and extracts the rock, fixes the concrete sections along the tunnel and continues to move forward while maintaining its trajectory," Stéphanie Laubert, Customer Logistics Agent.

The genesis of a project TMS/HERRENKNECHT Grand Paris

The main criteria needed to size the motor offering for an MSV destined for this type of project are the slope the vehicle will encounter, the curb weight of the vehicle and the gross vehicle weight rating. With this information, Antoine Desmyttere, Applications Engineer at Poclain Hydraulics, can propose the appropriate sizing. This enables us to define the needed torque and power of the motors, the speed of the empty and loaded vehicle and its braking capacity (dynamic brakes and parking brakes). In this example, the MSV automatically adapts the vehicle speed depending on whether or not it is loaded from 0 to 12 km / hour to 0 to 25 km / hour thanks to the two displacements of the wheel motors. Beyond these specifications, the current safety standards for underground work sites require TMS/HERRENKNECHT to use flame-retardant hydraulic oil, which is compatible with the dynamic immersed multi-disc brakes and parking brakes integrated in the motor bearings.

"Poclain’s technical support is 100% satisfactory. During the preliminary study with the sales engineer and the Poclain design office engineers, the specifications are validated in 80% of cases for known applications. In more complex applications with greater constraints, there is a lot more work. And we are very satisfied with it," shares Nicolas Lanard, Project and Field Service Manager at TMS/HERRENKNECHT.

Poclain Hydraulics’ MHP motors are also particularly well suited to meet the needs of machines in this industry because the integrated dynamic brakes deliver a real technological advance in terms of performance and reliability.

TMS/HERRENKNECHT and Poclain, an exclusive relationship

When it comes to wheel motors with integrated braking systems, TMS/HERRENKNECHT is in an exclusive relationship with Poclain Hydraulics. “Poclain is in a niche market with few serious competitors,” adds Nicolas Lanard. “[Poclain has] a clear advantage with the compactness of the product, even more so with the integration of all the braking functions: parking, service, emergency. Another advantage when it comes to our application, we need very high torque at low speed for very heavy loads ".

Since 2016, no less than 140 Poclain Hydraulics motors have equipped TMS' MSVs and PSVs operating at the bottom of the tunnels of Grand Paris. The company was involved in the construction of Lines 11, 14, 15 and the extension of the RER E EOLE for the Alliance Group and for the Spie Batignolles-VINCI Construction Group. In 2021 TMS will be tackling Line 18.

A "remanufacturing" offering

After good and loyal service on a site, the vehicles can benefit from TMS’s recent "reman" offering, taken advantage of by 95% of their customers. “Our MSV and PSV are used in a very harsh environment,” explains Nicolas Lanard. Due to mud, dust, cement and mortar, maintenance and regular cleaning are important. Every time they exit the tunnel on Line 15, they are thoroughly cleaned.”

At the end of a project, the motors are completely overhauled and benefit from a new warranty. As part of the reman offer, Poclain receives the hydraulic motors and carries out a full refurbishment of the systems. “The robustness of the product is very satisfactory. We never have an issue with Poclain motors, ”says Nicolas Lanard. However, adds Laurent Camin "one of the important elements of the reman service is the brake inspection". Poclain motors are then returned to TMS/HERRENKNECHT with a new manufacturer's warranty. The end customer wins because it is delivered twice as fast. “The reman in terms of cost and time meets our expectations. It’s working very well,” assures Nicolas Lanard.

Annex:

Grand Paris metro lines:

Ligne 14 Sud | Ligne 15 Sud | Ligne 15 Est | Ligne 15 Ouest | Ligne 16 | Ligne 17 | Ligne 18

Want to learn more?