ADDIDRIVE OPTIMIZES THE PRODUCTIVITY OF GEIGER’S FLEET

ADDIDRIVE ENHANCES GEIGER’S PRODUCTIVITY

Geiger adopted AddiDrive back in 2006 on its 4x2 tractors, powering the front axle with hydraulics. The hydraulic drive in the front axle beat the conventional all-wheel drive and the 6x4 tractor with semi-trailer:

“We went for Poclain Hydraulics’ solution, branded HydroDrive on MAN and HAD on Mercedes-Benz trucks. Our operators use it 5 to 10% of the time: to enter and exit a construction site and travel on a steep grade. Compared to a mechanical all-wheel drive, each truck gives us an extra payload of around 750 kgs. This increases our productivity, as we make fewer trips to and from the construction site.” says Andreas Weber, Logistics Manager at Geiger.

“Our operators also appreciate AddiDrive because the truck is easy to manoeuvre and position”. Besides, hydrostatics consume less fuel than a mechanical axle and reduce carbon emissions. Last, the truck height is the same as a standard truck, given that the hydraulic components are compact and connected using flexible hoses. So driving is more comfortable, and the truck dimensions remain unchanged. Trucks equipped with AddiDrive are a smart alternative to 4x2 and 4x4 mechanical trucks. AddiDrive provides the traction required to prevent getting stuck when the terrain is rough. This results in optimal productivity. Furthermore AddiDrive prevents slipping, so the tire mileage is higher. The impact of AddiDrive on fuel consumption and payload is also minimal compared to a standard truck. Finally, with AddiDrive the total cost of ownership is lower than with both alternatives, standard and mechanical all-wheel drive truck.

ADDIDRIVE ON GEIGER SPECIALTY TRUCKS

Besides the articulated tippers, Geiger has equipped ten specialty trucks with AddiDrive. First, they feature it on rigid 6x4H truck-mounted cranes, which are used to transport equipment, material and containers. They also use rigid 6x4H trucks paired with an additional two-axle trailer. This configuration enables the truck to transport 24 tons of payload. Two different materials can be transported simultaneously, which is an asset on small construction sites. Highly versatile, the trucks are also low on fuel consumption with an AddiDrive-powered axle at the front and a liftable axle at the rear. Additionally, thanks to the traction on the front axle, mobility is optimal.

Geiger also operates rigid 8x6H tippers in their gravel pits. When the truck goes up a steep grade, its length may cause the front axle to lift from the ground. With AddiDrive on the second axle, the truck has more traction and can climb up the slope effortlessly. Furthermore, the hydraulic axle reduces the turning radius, so the truck is more manoeuvrable.

ADDIDRIVE PAVES THE WAY TO BOLDER TRUCK DESIGNS

“We’re delighted with AddiDrive and our drivers are asking for it on trucks that don’t feature it. We need 6x2 rigid trucks with a lift axle on the rear for a special application. Adding AddiDrive to the lift axle would give us more manoeuvrability and payload”, Andreas explains.

Today AddiDrive equips thousands of vocational trucks across Europe and the US. The OEMs offer AddiDrive on a wide range of truck configurations. Furthermore, as contractors look for new ways to reduce the cost of moving materials, opportunities arise for body builders to design special non-standard AddiDrive trucks that meet their niche requirements.

AddiDrive was launched in 2005 to help vocational truck drivers cover the last mile on rough terrain. Ideal on construction, earthmoving, forestry, utility and heavy haulage trucks, it has been adopted by leading truck OEMs such as MAN, Mercedes-Benz, Renault Trucks, Terberg Techniek for Volvo, Iveco, Paul Nutzfahrzeuge for DAF and TDS for major US OEMs.

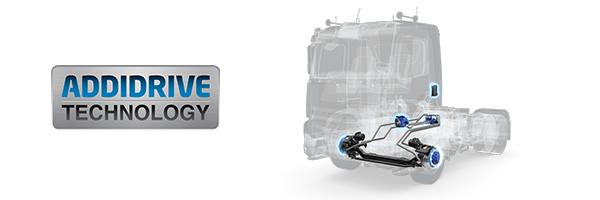

AddiDrive is a hydraulic hybrid transmission that transfers torque to a non-mechanically powered axle when needed. AddiDrive consists in a complete system with two hydraulic motors in the wheels, a pump, a valve and an electronic control unit.

Poclain Hydraulics contact for AddiDrive: Paola Ipsa, AddiDrive Trucks Marketing